Personalized ceramic printable ink for patient specific implant fabrication (InCePt)

personalized-ceramic-printable-ink-for-patient-specific-implant-fabrication

Background

The aim of this project was to develop and commercialize a chairside CAD/CAM solution for use in CMF indications. This innovative solution rested on the freeform fabrication process (bioprinting) developed by regenHU Ltd and a proprietary hydraulic calcium phosphate ink. In collaboration with ARI and University of Berne, the technology which is currently in a pre-prototype phase was physically and clinically assessed in order to gain market approval. One of the crucial goals given to the ARI team was to develop a formulation ink product for chairside manufacturing solution.

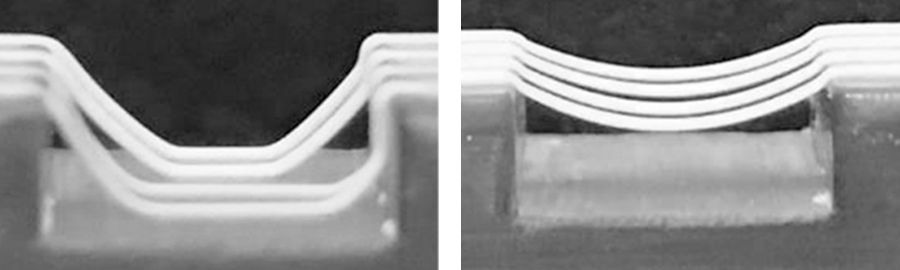

A novel printing approach was developed focusing on improving the shape fidelity of the printed cement past. The initial rationale was that: by achieving a high accuracy and shape fidelity of the printed structures, i) better control over the overall shape will be achieved, ii) better control over the mechanical properties obtained and iii) better ability to assemble ceramic printed structure with personalized implants or others mechanically or biological relevant printed structures.

The main scientific concept developed here was to use a co-axial extrusion technology for the printing of the reactive cement with a solvent or a mixture of solvents to initiate hardening of the extruded cement past and its stability during the printing step (Figure).

Fund:

CTI/KTI (nr 18060.2), ARI Funding: CHF 292‘700, Period: 2017-2019.

-

Publication

Bagnol R, Sprecher C, Peroglio M, Chevalier J, Mahou R, Büchler P, Richards RG, Eglin D.Coaxial micro-extrusion of a calcium phosphate ink with aqueous solvents improves printing stability, structure fidelity and mechanical properties. Acta Biomater. 2021;epub Feb 22. https://doi.org/10.1016/j.actbio.2021.02.022

-

Presentation

Sprecher CM, Thurner M, Büchler P, Richards RG, Eglin D. Improved post-processing stability of a 3D printed cement paste via co-axial extrusion of organic solvents. 2018 SSB+RM (poster).

Bagnol R, Sprecher CM, Peroglio M, Mahou M, Buchler P, Lieger O, Richards RG, Eglin D. Improving shape stability of patient-specific calcium phosphate bone substitutes using co-axial 3D printing. 2020 WBC virtual (poster)

Bagnol R, Sprecher C, Peroglio M, Chevalier J, Ligier O, Mahou R, Büchler P, Richards RG, Eglin D. Coaxial micro-extrusion of a calcium phosphate ink with aqueous solvents improves printing stability, structure fidelity and mechanical properties. 2021 ES Biomat virtual (poster)

-

Partner

Thurner M, RegenHU Ltd, Villaz-Saint-Pierre, Switzerland

Büchler P, Institute for Surgical Technology & Biomechanics, University of Bern, Switzerland

Lieger O (MD), Department of Cranio-Maxillofacial Surgery, Inselspital, University Hospital Bern, University of Bern, Switzerland